How in the world can you tell which of hundreds of ink companies to trust?

At trade shows and sign expos around the world you see dozens of booths that offer after-market ink. But when I visit printshops, they often tell me horror stories of third-party ink that clogged their heads. The ironic fact is that most of this clogging ink is from one or two really large international brands ! But obviously some of the clogging is caused by low-bid cheap ink from elsewhere.

In one case the end-user returned to original Mimaki inks (this was eight years ago we learned about this); in the other case (2010), the owner decided to move from the original Toyo inks from Japan and he opted for AT Inks from India. The point is that even big name brands, even Fortune 500 ink companies, also occasionally have a bad batch.The most recent example is another Japanese mild-solvent ink company that had a bad batch of magenta ink about five years ago. I have heard of the problems this one batch caused to ColorPainter printshops in almost every continent I have visited. These are the reasons that FLAAR began a long-term search for reliable after-market ink companies.

If the top ink companies in the highly developed countries had occasional bad batches, and if several big-name ink companies have problems with clogging, then you might as well at least find inks at lower prices. And you may find some of these reasonably priced inks have quality control and take pride in their ink chemistry. So every year FLAAR visits ink companies to learn which we should consider listing. We added AT Inks and Sam Ink during 2010. But low-bid after-market ink companies spoil the situation because their cheap ink causes more headaches than the big-name brands.

So FLAAR has been working to establish which ink companies are reliable, and which ink is good. We do this by doing a lot more research than just looking at the ink: we visit the ink factory, in-person. Then FLAAR makes the effort to visit end-users who utilize the ink so we can determine how this ink works out in the real world.

SSo the next time you go to a sign expo or trade show, you can visit the booth of Sam-Ink and realize that FLAAR has inspected their facilities (three times during the last five years) and checked their inks in Hewlett-Packard Designjet 5000 and 5500 printers and HP Designjet 8000s, 9000s, and 10000s versions of Seiko ColorPainter 64s printers. |

| Nicholas Hellmuth at Sam Ink site visit showing the HP L25500. |

Compare prices. Is this a good way to insure a good ink?

There is plenty of cheap ink available for HP 5000 and HP 5500 printers. But you never know where it really comes from or what is really inside the ink.

And can you get tech support? Or is the box-pusher just selling a bottle and ink and you have to figure out ICC color profiles yourself?

For all of these reasons we suggest looking at a company that has a respected name in the industry. A good start is if the ink company has a booth at the major trade shows, and franchises (distributors) around the world.

Reality with any and all ink, including original OEM ink

If you interview a hundred printshops, you will find someone, somewhere, who has had clogged nozzles with every brand. But often this is the poor cleaning procedures of the printer operator. Other times it is dust and grit from a flatbed cutter that is causing the heads to clog. So it is not always the ink that is entirely at fault.

I have heard complaints about a few batches of ink from Sun (the UK and German company; one of the really large international companies). Several people told me Triangle ink has clogged their heads, though I am sure there are thousands of end-users who like this ink since this is a large and reputable company.

But these are bad batches of ink that is otherwise fairly good. I consider the ink used in the Seiko ColorPainter as one of the better inks, especially for color saturation (meaning that it has good pigment load). But one single bad batch of Magenta for that printer, years and years ago, is still remembered literally around the world.

The point of this is that no one is able to guarantee any ink: what is good today can have one bad batch tomorrow. But what is crucial is to find the ink companies that stand behind their ink, they correct the batch once they find one batch of one color had an error. How does FLAAR do this?

FLAAR evaluation process of an ink company and its inks

|

| AstarJet Epson at Sam Ink site visit, 2010 |

I explain this best in the full-color PDF that we are preparing now, but in essence we visit and inspect the company, we learn who their contacts in the industry are (you can tell a lot about a company by who does business with them). And most importantly, FLAAR interviews end-users. So we inspect the company (the people who own and operate the company, management and chemists), the manufacturing facility, and end-users.

FLAAR does this as a professional service, as consultants, since obviously the airfare, hotel, meals and related costs for site-visits need to be covered. This service is not automatically available to every ink company because we need to first discretely check around and learn about an ink company before we accept an evaluation project with them. We have accomplished full evaluation projects of several ink brands and starting about 2010 we began to evaluate Sam-Ink. FLAAR has also been the guest at the R&D facilities of many other ink companies around the world.

Second step in ink evaluation is to visit end-users (print shops)

While at Sign Istanbul in late 2010 the distributor of Sam*Ink (Inka Teknik.com (DIC Group)) very kindly arranged a visit to a print shop that had more than a dozen HP Designjet 5500 printers. They were each using aftermarket ink cartridges from Sam*Ink.

This print shop was producing top quality signage for elite brand names. So clearly the client, and the print shop managers, were content with the ink.

We also just received an e-mail from one of the largest décor printing companies in the US. They use Sam*Ink to produce décor: décor is mass-produced giclee for decorating hotels, motels, and homes.

So clearly clients of all sizes, and in many countries, are content with this brand of ink.

Sam Ink for water-based inks in thermal inkjet printheads

During 2001-2006 the largest evaluator of HP Designjet printers in the world was the FLAAR Reports. We evaluated virtually every HP Designjet printer model in those years. We had dozens of printers in our test facilities at two universities. During this period we did not have time to evaluate after-market third-party inks: we were too busy evaluating the original inks (which produced beautiful results for interior signage, giclee, and fine art photography).

|

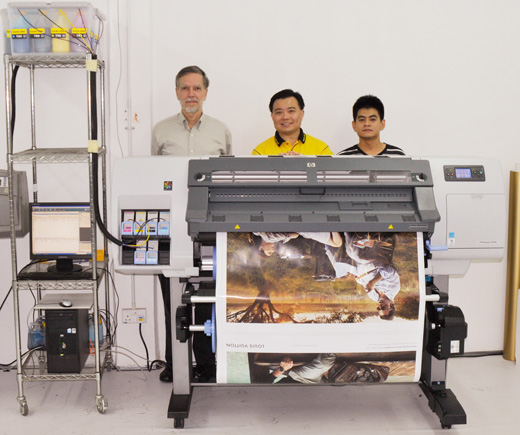

| Here is Dr. Nicholas Hellmuth (at the right) with Mr. Sam Leong (at the left) at the Sam Ink factory in Singapore. in a modern industrial park in Singapore |

But these projects are long over and now since actually several years we realize that evaluating after-market third-party ink is a valued service to the over one million people that read our web site network. And since tens of thousands of people bought HP Designjet printers as a result of FLAAR reviews in those early years, it is appropriate that we follow-up and provide additional services to evaluate after-market water-based inks for them.

Sam*Ink is a company I noticed for many years because of their conspicuous yellow logo color. There are so many ink companies that there is not time to visit with every one at a large trade show, but probably at Dubai or elsewhere, I visited with the owner, whose name is obviously Sam (English is the official language of Singapore).

|

This is the HP Designjet Z6100 using the Sam inks at the factory visit. |

The full FLAAR Reports are now being issued: one on water-based inks (HP Designjet 5000, 5500, Z6100 and CAD-GIS printers HP 1050 and HP 4500; a separate report on mild-solvent inks for the HP Designjet 8000s, 9000s, and 10000s.

You can opt for bulk-ink system, or you can opt for remanufactured HP cartridges.

|

One reason that this ink is good is because the company focuses on only certain printers and certain printheads. So the printhead engineers, the ink chemists, and software engineers, and managers can concentrate on making appropriate ink for specific model printers.

|

During mid-February 2014 we visited two more print shops

to inspect which after-market ink they used for their HP Designjet 5500

We will be updating our various reports based on recent site-visit case studies. We visited three print shops in Singapore in mid-February.

- one had lots of Mutoh printers and two HP Designjet 5500 models; the HP printers were using ink from Sam-Ink. Of the seven Mutoh printers, about half were using eco-solvent ink from Sam-Ink.

- The other had four Roland printers (the oldest of which was using Sam-Ink refills)

- The third printshop had a HP latex printer (HP Designjet L26500) using Sam-Ink and a HP Designjet 5500 (also using Sam-Ink).

Most of these print shops had been using Sam-Ink for many years.

|

|

|

|

| DOWNLOAD | DOWNLOAD |

Most recently updated Feb. 18, 2014, after visiting two print shops in Singapore who are still using Sam-Ink.

Updated December 7, 2010, after visiting a printing company in Istanbul which was successfully using Sam-Ink in more than a dozen HP Designjet 5500 printers.

First posted May 17, 2010.