Staedtler Lumocolor ink for wide format inkjet printers.

|

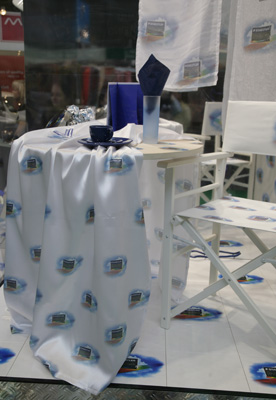

| Side view of Staedtler printer at Photokina Trade Show, 2004. Printing some sample to proove ink quality. |

When I first saw the exhibits of Staedtler Lumocolor ink at Photokina 2004 I was impressed at the sheer number of diverse materials that this water-based ink could print on. The Staedtler managers were hospitable, and the Staedtler company has a good reputation for its other ink products, especially in pens and markers.

But the inkjet ink would not adhere well to non-absorbant materials (such as PVC), so was not of much interest to everyone who wanted to print traditional signage.

Plus many materials required a special form of heater on the printer: so no normal printer could easily handle the ink.

Experiments in Japan did not produce adequate positive feedback. There were never enough installations in the US to get good feedback at all . Thus it was sad to see such a promising ink not succeed.

Since this is a water-based ink we will cover it on this www.wide-format-printers.org , but since this ink prints on signage material used by print shops that tend to use eco-solvent, mild-solvent, full-solvent, or UV-curable inks, we will also including mention on our signage ink site, www-large-format-printers.org.

Why was Staedtler Lumocolor ink not successful?

One word summarizes the main problem: industry politics.

The occasional chemical issues were only a fraction of the problem. Most of the issues were corporate: for example they had the wrong distributor in the US (a good person and good company but not adequate for décor, architectural materials, or signage on unique materials).

Lumocolor could have, and should have, been more successful. But the internal politics of how it was handled and the opposition by Epson to any outside ink going through their printheads combined to result in a lack of acceptance of the ink. Any company with a new ink today can learn from how, and why, earlier inks failed.

Please realize that “failed” does not mean it was an inadequate ink chemistry. “Failed” is usually because of chemistry of the corporate management policies and the reality of competing printer manufacturers. Any ink that is marketed only on the basis of its chemistry will not tend to be successful in the real world of wide-format inkjet printers.

Fortunately Staedtler Lumocolor ink is still available for niche market applications with individually retrofitted printers, such as by SmartColor in Italy. This ink is still being used in Japan, but in very limited applications and by only a few companies. But at least in Japan they selected a good distributor.

HP latex ink is another ink that requires a heater

|

| Different materials printed in Staedtler printer at Fespa Trade Show, 2006. |

I have long felt that Staedtler Lumocolor ink is one of the most interesting inks available. Unfortunately, no printer manufacturer was brave enough to be willing to go out on a limb and develop a printer that could handle it. But now HP has shown that it will at least try when a new ink requires special printheads and an even more special heating/drying system. Since HP has never made it's own heating drying system (i ts solvent printers HP 9000s , HP 8000sr , HP 10000s were all made by Seiko, based on the original Seiko ColorPainter 64S ), it has been interesting to see the printer that is intended to use the new HP latex ink, especially the HP Scitex LX600 and HP Scitex LX800.

The first printer that utilizes this HP latex ink has been launched at DRUPA 2008: this is the HP Designjet L65500 . Then in 2009 smaller versions came out, the HP Designjet L25500 . Now the L65500 has been given a new name: HP Scitex LX600 and HP Scitex LX800.

One difference between HP latex ink and Staedtler Lumocolor is that HP latex ink is aimed directly at signage, whereas Staedtler is primarily showcasing its inks ability for specialty items, including thick rigid materials via a flatbed. The first generation HP latex ink will not print on flat rigid materials because the heaters are on the bottom. Staedtler's ink can accept heaters at the top.

But what we can learn about latex ink is that the main reason it has been successful is that HP designed a printer from the ground up that could provide the furnace-like heaters required by HP latex ink. Staedtler is an ink company, not a printer manufacturer. We explain in the new FLAAR Reports why all this caused the most promising ink of 2004 to fail in the marketplace.

Actually most alternative inks require a heater

About six years ago, the Encad VinylJet used ink from DuPont. It required a lot of heaters. Unfortunately Encad's ink delivery system and printheads were primitive, and Kodak's management drove what was left of the company into the ground. Plus it was a first-generation ink and not enough media was available for it.

HP has a long more clout for launching its latex ink. HP has more resources than Encad or even Kodak combined. HP has been relatively successful with their latex ink because of the huge resources they directed to their new products.

One new alternative ink from Europe requires a heater. These are not the searing hot mercury-arc UV lamps that UV-curing needs. The alternative water-based and alcohol-based inks simply need some medium heat from the top (since these inks are aimed at printing on thick materials, such as wood, stone, acrylic panels, glass, etc). Kiian ink is one alcohol-based ink that can print on almost all surfaces: décor and signage.

|

|

| Three-quarters view of a Mimaki printer outfitted to handle Staedtler Lumocolor ink , Photokina 2004. Yes, you can use this ink in most Mimaki, Mutoh, Roland, or Epson printers, but…But it needs a special heater to print on vinyl and non-absorbent materials (not the heater that is already on a solvent printer, because Staedtler Lumocolor is not a solvent ink). |

So far all alternative inks have failed in the market place. Why?

There was a recent article in SIP magazine, and one of the questions was on ink. One of the commentators politely stated that Lumocolor ink showed promise but was not successful in the market place. FLAAR was quoted several times in the same German article.

Since 2008 FLAAR has been doing an in-house study (meaning for ourselves, not yet commissioned by an outside company; but available under consulting) on why all alternative inks have failed.

This study also asks, and answers, questions about HP latex ink: what are its stumbling blocks; what are its selling features. But HP latex ink is actually not as innovative as is Staedtler Lumocolor because latex ink can't print on diverse materials and can't print on any thick or rigid material.

FLAAR is increasingly now a consultant to ink manufacturers and printer manufactures and media manufacturers on which inks to look at, what to be wary of, why so far all these inks have failed, and what it will take for a future ink to succeed.To obtain the consulting parameters, e-mail [email protected] or telephone FLAAR, 1 419 823-9218.

Please realize these are NOT numbers to ask questions; to ask questions you need to fill out the Survey Inquiry Form, and most questions are answered by the FLAAR Reports that you can ask for. If you need consulting, then you can use the e-mail or telephone number to request consulting on a normal fee basis.

If you wish to consult with Dr Hellmuth at any trade show, he is also available, as well as at some VISCOM fairs in Europe. Please understand that telephone consultation requires a prior appointment and taking care of the consulting fee (or if you have ordered a requiste quantity of FLAAR Reports in order to get consulting at a reduced rate).

But one new water-based ink is successful: Sepiax

Sepiax ink is a water-based resin ink and does not require special heaters for most signage materials. The normal heaters that are already on a Mimaki, Mutoh and Roland eco-solvent printer are plenty good enough to handle Sepiax water-based ink. And, if you had other features to the printer, Sepiax ink works even better.

|

Here is Dr. Nicholas Hellmuth at Sepiax company.

Sepiax ink does have an odor, but it is mild compared with the odor of UV or Solvent inks. |

Sepiax ink prints on uncoated Tyvek, uncoated newsprint, Kraft paper, PVC, metal, leather, and diverse other surfaces (but is not intended for glass).

So far it appears that Sepiax is successful in all the aspects where Staedtler Lumocolor ink failed: a new FLAAR Report will discuss these inks, and will explain why one ink failed and the other has, so far, been increasingly successful.

More to come:

there are more innovative resin inks to be launched in 2010 and 2011

There is more to come. What is interesting is whether the new ink companies will be willing to learn from the other equally exciting inks.

Remember, the success of an ink has really nothing to do with the chemistry of the ink: the success of an ink is politics, positioning, PR, and partnering.

Can Lumocolor ink be rescued?

Yes and no. Lumocolor ink could have been rescued in 2004 through 2008 if knowledge about what causes an ink to succeed, or fail, had actually been applied.

But we are no longer in 2004 or even 2008. This is 2010: HP latex ink is getting entrenched (because it had no competition until Sepiax came out). So now Sepiax ink is getting started. Plus, at JapanShop 2010 expo and subsequently, there were rumors of several other new inks. I also heard of several exciting inks last year at SGIA. And also now in 2010, since more companies realize that FLAAR is available as a consultant on inks, we get more ink, ink component, and ink distributor companies coming to us, discretely, to ask for assistance.

Most recently updated May 17, 2010.

First posted March 18, 2008. Updated February 8, 2009, May 21, 2009 , and March 2, 2010.